MORE Reasons Why American V8s Make Low Power for Their Size August 06 2018

In our previous article, we talked about some of the reasons why American pushrod V8s have a hard time getting the most out of their displacement. We talked about redline limits, head flow limits, compression ratio limits, and variable valve timing difficulties. Now, let's talk about a few more minor and nuanced reasons why some American V8s can have low specific outputs compared to some of their European and Japanese counterparts. In our previous article, we compared the Chevy LS3 6.2L V8 to the BMW S65 4.0L V8, so we'll continue to use these two engines for comparison.

1. Cylinder firing order. The overwhelming majority of American pushrod V8s have an uneven cylinder firing order. Instead of having exhaust pulses alternate between the left and right cylinder banks in a left-right-left-right order, the pulses go right-left-right-right-left-right-left-left. What you want for maximum power is a firing scheme that alternates consistently between cylinder banks. If you are using a tuned exhaust manifold, you can use the pressure waves bouncing around inside the manifold to help draw exhaust out of the cylinder at the end of the exhaust stroke. This removes more of the exhaust, so there is less leftover exhaust in the next engine cycle, and it also subsequently allows the air/fuel mixture to flow in easier. This creates more flow through the engine and therefore more power. We won't go into the details of how this works, because that is a whole article itself. If the pressure waves inside the manifold are inconsistent because of an uneven firing order, you lose some of this effect. The pressure waves get disturbed when two cylinders in the same cylinder bank fire consecutively.

We're not going to get into a full explanation of why a manufacturer would choose an uneven firing order, but the short of it is that it reduces the amount of vibration that the engine produces.

In this case, both the LS3 and the S65 have uneven firing orders. The overwhelming majority of V8s have uneven firing orders, except for the most performance-oriented engines. Because of this, it's not fair to single out American engines for having an uneven firing order, but it is one area that could be improved.

On a side note, Ford uses a V8 with an even firing order in their 2017 Shelby 350 GT, and it makes 100 hp per liter. The relatively high specific output can't solely be attributed to the even firing order, but it certainly helps.

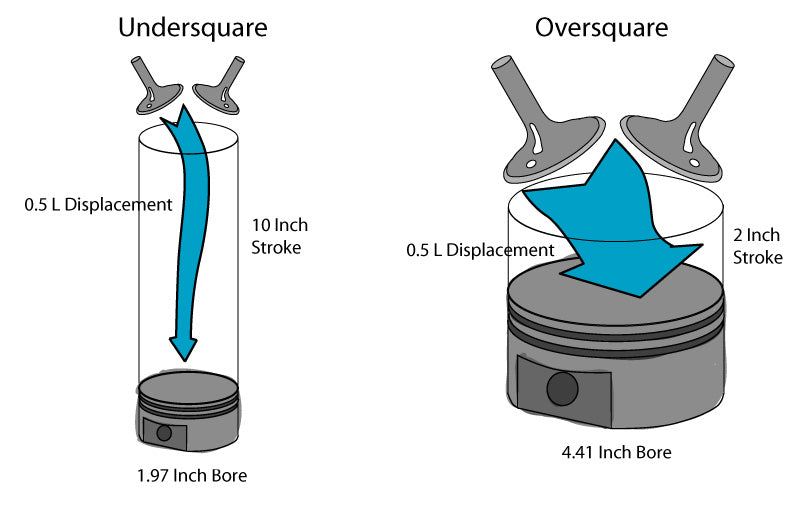

2. Undersquare engine. What is an undersquare or an oversquare engine? Take the bore and the stroke of a cylinder, and compare the two numbers. If the bore is larger than the stroke, the engine is oversquare. If it is the opposite, then the engine is undersquare. This ratio of the bore in comparison to the stroke gives us an idea of how the swept area of the piston looks like. Is it flatter, like a tuna fish can, or taller like a soup can?

Why does this matter? Whether an engine is more oversquare or undersquare has an effect on whether the engine will produce less torque, but maintain that torque at high rpm (for more power), or produce more torque, but have that torque drop off at high rpm (for less power). Why is this so?

Let's imagine a hypothetical engine that is ludicrously undersquare. Imagine the intake stroke. The valves will be tiny compared to the overall volume of the combustion chamber and have a hard time flowing all the fuel and air down into the bottom of the cylinder. Additionally, the fuel air mixture has a long way to travel to the bottom of the combustion chamber in a short amount of time. The piston will also be traveling ridiculously fast to cover so much distance for each revolution of the crankshaft.

Now, let's imagine a hypothetical engine that is ridiculously oversquare. The bore is large in comparison to the stroke, so there is a lot more room to make the valves larger. The fuel-air mixture also doesn't have to travel as far or as fast to completely fill the combustion chamber. Intuitively, you can see how an oversquare engine will flow much better. Large valves and a shallow stroke allow for efficient flow, which is crucial to making high-rpm power.

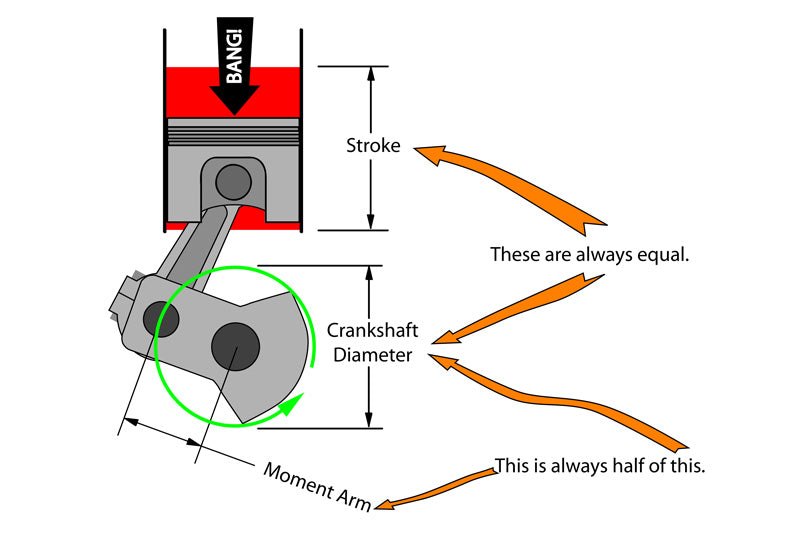

That is not to say that undersquare designs don't have their own advantages. The main benefit to an undersquare engine is its greater mechanical advantage on the crankshaft. A long stroke means there will be a large crankshaft diameter, which means there will be a longer moment arm for the explosion to exert on the crank. Intuitively, we can see that longer the moment arm is, the more leverage the explosion has on the crankshaft. This means more torque output. It may make sense to put an undersquare engine in a tractor or truck, where low-rpm torque is what is most important.

Let's compare the bores and strokes of the GM LS3 and the BMW S65.

Both engines are oversquare, reflecting sporty intentions from their designers, but the BMW S65 is more oversquare, helping it to develop higher horsepower per liter than the LS3.

3. Overall cylinder size. BMW V8s are mostly between 4.0L and 4.4L. If the cylinder size is about 0.6L per cylinder, and displacement needs to increase beyond that, BMW will typically add cylinders instead of increasing bore or stroke dimensions further. For example, BMW makes V10s and V12s instead of V8s when displacement gets to 5.0L or above, thereby keeping the cylinder sizes from getting too large. What this does is keep the parts light enough to still be able to rev the engine to high rpm. Why can't a hypothetical engine that is 10% bigger rev as high as its smaller counterpart? This isn't intuitive to everyone, so let's look at an example.

Mass of an object increases at a cubic rate, but the material strength only increases at a square rate. If we take a hypothetical cube and make it 10% bigger, let's see what happens. Let's look at a cube with an original size of 10 inches. There would be 1000 cubic inches (10 in x 10 in x 10 in) inside this 10 inch cube. What happens when we grow the cube 10% to 11 inches? Now there are 1331 cubic inches (11 in x 11 in x 11 in) inside this 11 inch cube. The size has gone up 10%, but the volume and mass have gone up 33%.

What about the strength? Let's say that material has a tensile strength of 1 pound per square inch. So let's go back to our original 10 inch cube. If we put the cube in tension, the cube has a cross-sectional area of 100 square inches, and a hypothetical tensile strength of 1 pound per square inch. Therefore, the cube can withstand 100 pounds of tensile force. Let's grow the cube 10% and see what happens. Now, it is an 11 inch cube. The cross sectional area is now 121 square inches (11 in x 11 in), and the maximum load the cube can withstand is 121 pounds. This is a 21% increase in strength, compared to the 33% increase in mass.

Bringing this concept back to an engine, let's look at the implications on a valve, since valve float is often the limiting factor for engine speed. If we grow the entire engine 10%, the valve mass increases 33%. The spring that keeps the valve closed then needs to be 33% stiffer, the rocker arms will see 33% more load, the camshaft will see 33% higher load, the bolts and bearings for all these parts will see 33% higher load. However, all these parts will have only gotten about 21% stronger. This 21% strength increase is an oversimplification because most parts aren't purely in tension, but the concept is generally valid. Everything will need to be made beefier, but if you simply make the parts thicker, then you're adding even more mass into the valvetrain, which further works against you.

You can see how it gets exponentially harder to produce a high revving engine as the cylinder size increases. In our previous article "Why American V8s Make Low Power for Their Size", we mentioned lower redlines as one of the things holding back American V8s, and attributed the lower redline to pushrod engines inherently having more valvetrain mass because of the design. This is the main reason for having a lower redline, but we can also add that a large cylinder size does not help the situation.

Closing thoughts. So these are some more minor reasons why many pushrod V8s have low specific outputs. So why wouldn't GM make the necessary improvements to increase power? I would speculate that using a pushrod architecture is more of a conscious design decision than an inability to make a more sophisticated engine.

The pushrod engine is an old, simple design that forgoes many power-maximizing features seen in modern engines, but what it gains is the ability to have a large displacement without excessive size or weight. The relatively compact size of the LS engine is why so many people can swap LS engines into their cars where straight sixes or inline fours once resided. I don't have a profound appreciation for pushrod engines, but I can see why many American manufacturers choose them, and why some people love them.

I hope that the pushrod fans can understand some of the negatives of pushrods a little better, and I also hope that the pushrod haters can start to see how the pushrod design strategy has its merits. Instead of denying our engines' flaws, we need to embrace them and own them. Once we own these flaws, we take away the power of detractors. In other words, don't get butthurt if someone doesn't share the same horniness for your engine choice. There's no such thing as a perfect engine.

Related Articles: