Turner Motorsport E36 M3 (S52 Engine) Oil Pan Baffle Review January 22 2020

While we were putting safety wire on our oil pump nut, we had the engine oil pan out and figured we might as well put some baffles inside to prevent oil starvation in long sweeping corners. This is how the installation looks like and what we think of the kit. This review won't look into how effective the baffles are in keeping oil at the oil pickup, but rather at the fitment and quality of the kit.

After pulling the oil pan from the car, we have to separate the factory baffle by grinding off a rivet and then lifting the baffle out. We'll talk about how we go about reattaching the baffle at the end of the article, as we did something different from what the instructions suggested.

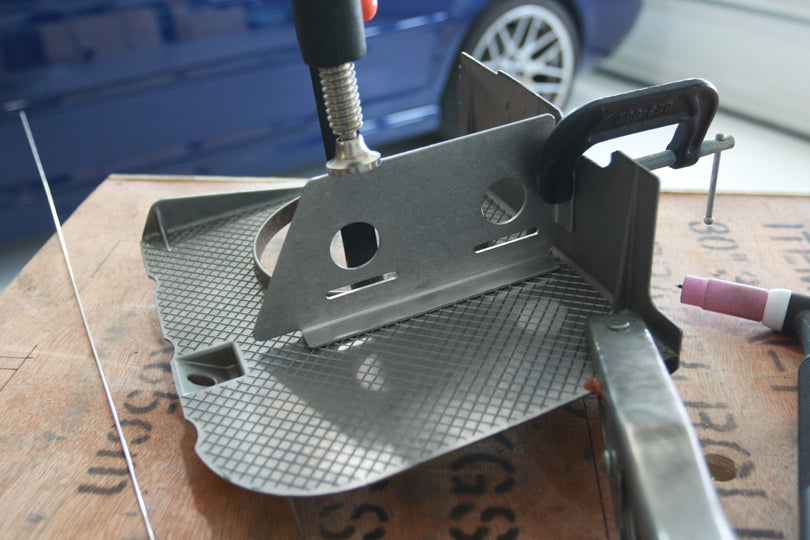

The kit consists of several pieces of formed aluminum sheet metal and some rubber flaps. Included were instructions with color photos. This kit requires welding on cast aluminum, which is more difficult than welding on sheet or billet aluminum because of the higher amounts of impurities in cast aluminum. We don't recommend trying to use this kit unless you are proficient with welding aluminum. You'll have to clean the aluminum and try to get all the oil off. The porosity of the cast aluminum oil pan will make it hard to get all the oil out. Burning out the oil with a propane torch may help. Once welding, you'll have to use high electrode-positive AC balance to blast the impurities away. You'll have to let the weld puddle form and sit for a moment to let the impurities rise to the surface. You'll use the clean filler metal to float the dirty metal to the top. You may need to grind the impurities off the top of the cooled weld and run another bead to add back some clean metal.

The fitment of the sheet metal pieces was good, but not perfect. There are certainly looser dimensional tolerances when it comes to casting aluminum oil pans compared to stamped oil pans. It is possible that the dimensional difference between oil pans means this kit fits some oil pans great and others not as great.

Fitment of this baffle was satisfactory to us.

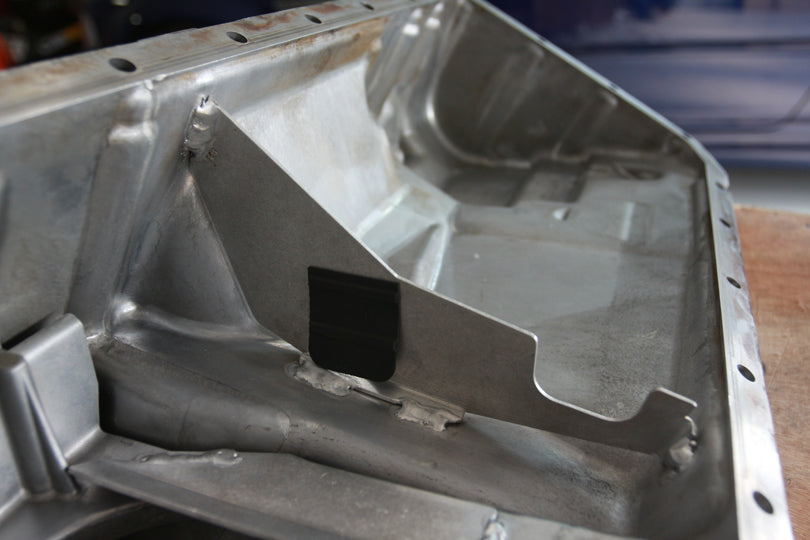

We ran weld beads shorter than recommended in the instructions. These welds are adequate for holding the baffle in place, and more welding just means more chance for the heat to warp the oil pan.

This baffle blocks the sloshing of the oil up out of the sump.

An item where we deviated from the instructions was tack welding the factory baffle back in place instead of drilling, tapping, bolting and sealing with silicone. Drilling a new hole in the oil pan introduces a potential failure point, which we don't prefer. We don't anticipate ever having to remove the factory oil pan baffle again, and if we did, we would just grind off our tack weld in the same way that we ground off the factory rivet. Sidenote: we hadn't anticipated having to weld this area, and we forgot to torch off the oil hidden in the pores of the cast aluminum. You can see the porosity in the melted base metal from the oil contamination. Torching off the oils makes a big difference in weld quality.

Here you can see the rubber flaps installed. They fit well and seem well suited to their intended purpose. We like the idea of rubber flaps instead of hinged aluminum flaps because of the potential of aluminum wear particles from moving aluminum parts. Additionally, any failure of aluminum hinges means aluminum parts floating around in the oil pan, ready to do engine damage. Lastly, rubber likely creates a better seal than aluminum. All this is speculation, and aluminum hinges are commonly used with no issues, but we like the idea of minimizing risk with rubber flaps.

Overall, we are satisfied with the quality of the kit. The sheet metal parts looked like they were cut on a waterjet or laser cutter with clean, precise cuts. The edges were also nicely smoothed over and deburred.

There is room for improvement in the fitment, but the fitment was reasonable and was able to be installed. It may take some finesse to weld some of the gaps, but is manageable by a decent welder. Again, cast parts often have some dimensional differences, so it is possible that your fitment may vary depending on the dimensions of your particular oil pan.

I would have preferred a better solution for reattaching the factory baffle, but either the suggested tap and bolt solution or a simple tack weld works. This is just us nit-picking.

Overall, this baffle kit saves significant fabrication time over making some baffles from scratch, and it takes a lot of guesswork out of the project. I saw a few places for improvement, but when it comes down to whether I would buy this kit again, I'd do so without hesitating.